By Mike Dimock, Ph.D./ Vice President, Field Development/ Certis Biologicals, L.L.C.

Bt: The first commercial bioinsecticide

Discovered at the turn of the 20th century in Japan and formally named soon afterward in Germany, the bacterium Bacillus thuringiensis (Bt) has been used as a bioinsecticide since the 1930s. Bt was first introduced to the US market in 1958 as Thuricide®, a still in commercial use and manufactured in California from the start. Since then, Bt products have become dependable tools for managing caterpillar pests in agriculture, forestry, floriculture, and home gardens, as well as in public health for control of mosquitoes and blackflies. The unique mode of action, natural origin, and robust safety profile of Bt provide growers flexibility in producing high quality crops while avoiding some of the challenges associated with synthetic chemical insecticides.

How does Bt work?

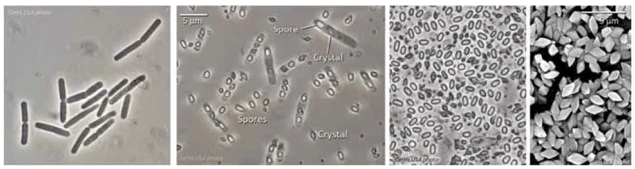

Late in its life cycle, during spore formation, a Bt cell produces insecticidal proteins known as delta-endotoxins, or Cry toxins because they form crystals within the cells. Bt spray products contain spores, crystals, cell debris, and other components of the harvested fermentation biomass (Fig. 1).

Figure 1. Vegetative growth, sporulation, and toxin crystal formation in Bacillus thuringiensis.

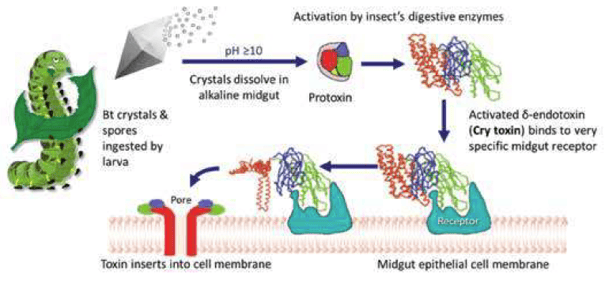

Upon ingestion of Bt spray deposits by a susceptible insect larva, the crystals dissolve in the alkaline environment of the midgut, releasing protoxin molecules which are converted to activated delta-endotoxins by the insect's own digestive enzymes. Activated toxins attach to highly specific receptor proteins on the surface of the cells lining the insect gut, then insert themselves into the cell membrane to open pores (Fig. 2). The resulting "ulcers" cause gut paralysis and stop insect feeding in as little as 30 minutes. Death usually follows within 1-3 days from starvation, osmotic shock, or septicemia as gut contents, including spores, leak into the bloodstream (hemocoel) and affect other vital functions.

Figure 2. Mode of action of Bacillus thuringiensis against Lepidoptera larvae. Diagram modified from R. deMaagd et al. (2001), TRENDS in Genetics Vol.17 No.4.

Laboratory bioassays with purified Cry toxins have found that caterpillars species differ in toxin susceptibility. Some species, such as cabbage looper, peach twig borer, and leafrollers, are quite susceptible to most Cry toxins, making them relatively easy to control with Bt sprays compared to others (most notably armyworms in the genus Spodoptera) that are less susceptible. Larval age and size also play a role in toxin susceptibility, with small larvae (1st and 2nd instars) requiring lower doses than mature larvae.

What kinds of Bt products are available, and what are the target insects?

There are many subspecies and strains of Bt, from which more than 700 unique Cry toxins have been identified to date. These are classified into 73 families (Cryl - Cry73) and numerous subfamilies (CrylA, CrylB, CrylC, etc.) and smaller units (CrylAa, CrylAb, CrylAc, etc.) based on similarity of amino acid sequence. Most commercial Bt spray products targeting caterpillar pests (Lepidoptera larvae) contain B.t. subspecies kurstaki (Btk) or aizowai (Bta) and their associated Cryl and Cry2 toxins. Other Bt subspecies are found in products effective against larvae of Diptera (mosquitoes, blackflies, fungus gnats) and Coleoptera (some leaf beetles and grubs).

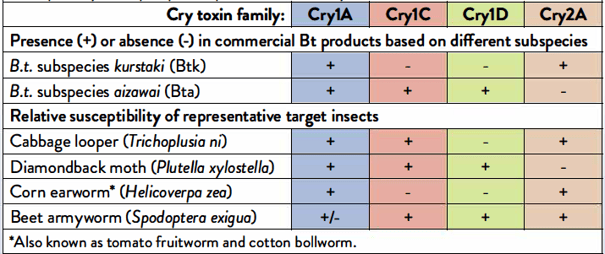

Btk and Bta strains differ in the types and amounts of Cry toxins they produce, and insects vary in susceptibility to individual Cry toxins. Cry toxins present in commercial Bt spray products and susceptibility of representative Lepidoptera species are indicated in Table 1. Products based on Btk are characterized by the presence of CrylA and Cry2A toxins. In addition to CrylA and Cryl D toxins, Bta is characterized by presence of CrylC which is lacking from natural Btk. CrylC is more toxic than others to Spodoptera species (armyworms), which are relatively insensitive to Cry1A toxins and therefore less susceptible to Btk.

Table 1. Cry toxin profile of Bacillus thuringiensis spray products (upper table) and susceptibility of Lepidoptera species to those Cry toxins (lower table).

What are some features of Bt that make it valuable for IPM?

Bt has characteristics that make it a valuable tool for integrated pest management, and most Bt spray products are also approved for use in organic crop production. The highly specific mode of action of Btk and Bta is limited to Lepidoptera larvae, with no toxicity toward beneficial insects (including bees), humans, livestock, or wildlife. Of course, this also means that Bt spray products will not control non-susceptible pests such as aphids or spider mites. But Bt sprays also will not flare secondary outbreaks of those pests by harming their predators and parasitoids. Most Bt products are exempt from US-EPA residue tolerance requirements, with no preharvest interval (PHI), or maximum residue limits (MRL) for exported commodities. Coupled with minimal re-entry interval (4-hour REI), Bt provides flexibility in crop and harvest management compared to pesticides requiring longer waiting periods before field re-entry and harvest.

Bt sprays tend to have short residual activity because of the effect of solar UV radiation on proteins. This contributes to the lack of residues, but may necessitate reapplication, especially in periods of rapid plant growth or sustained egg-laying by the target pest species. Residual activity can be extended by spraying late in the day (larvae continue to feed and ingest Bt at night) or tank mixing with a commercial sunscreen adjuvant. The proteinaceous nature of Bt gives it some natural rainfastness if spray deposits are allowed to dry on the plant for several hours. Most Bt spray products used in agriculture are dry formulations (water-dispersible granules or wettable powders) stable for 2-3 years at room temperature if kept dry in the original packaging. Refer to product labels for specific instructions on handling, storage, and use.

What is the role of Bt in insecticide resistance management?

The unique mode of action (IRAC Group 11) shows no cross-resistance with other insecticide chemistries, making Bt a good rotation or tank mix partner for insecticide resistance management. As with any insecticide, prolonged reliance on frequent Bt sprays (or repeated exposure to transgenic crops expressing Bt toxins) may result in development of resistance to one or more of the Cry toxins present in the product. However, research has shown that different Cry toxin families bind with different receptors in the insect midgut. Rotating Btk and Bta products can be a useful tactic for managing the risk of resistance, but as with all pesticides, overreliance on any single mode of action should be avoided.

What is the future of Bt in agriculture?

Since the mid-1990's, genes coding for Bt toxins have been transferred into plants to develop transgenic crops resistant to rootworms, bollworms, borers, and other insect pests. New Bt strains are still being discovered, and new proteins are still being characterized from non-commercial Bt strains. Some of these have shown activity against insects not targeted by current Bt sprays, such as plant bugs, thrips, mites, ticks, and nematodes. Even human cancer cells have been found to be susceptible to certain Bt toxins. New types of Bt toxin proteins have been engineered into transgenic plants to prevent or delay resistance to the Cry toxins also expressed in these plants. And researchers continue to investigate in finer molecular and genetic detail the process of receptor binding and basis of toxin specificity.

Despite more than a century of research and commercial development, Bt has not yet given up all its secrets. Not bad for an active ingredient that has been in commercial use since before most of today's PCAs were born!

This article appeared in the October 2020 issue of CAPCA Adviser Magazine. You can read the original here.

To see Certis Biologicals' full portfolio of Bt biolarvicides, click here.